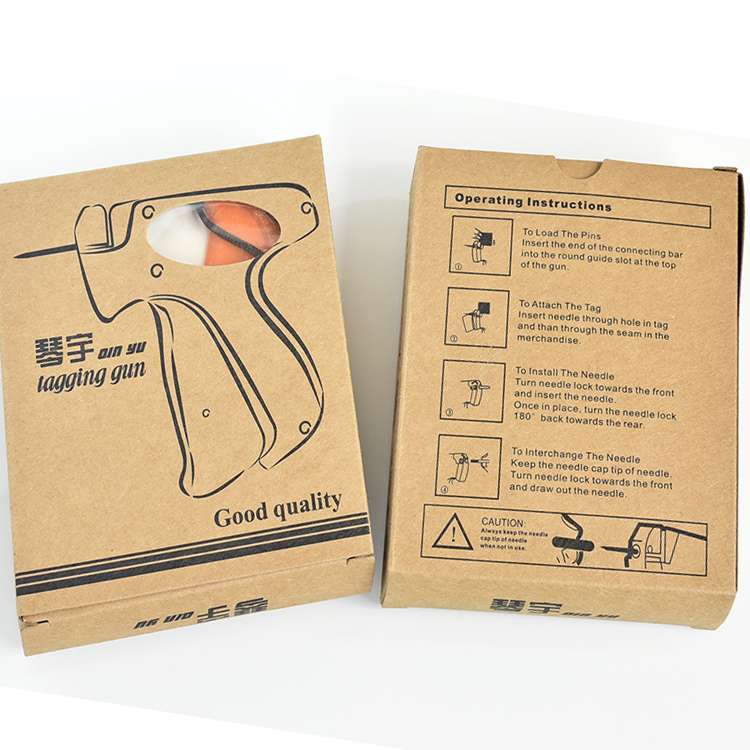

With the progress of modern industry, many traditional manual processes are gradually replaced by mechanized equipment. Among them, in the garment manufacturing industry, "Qin Yu 8S plastic needle thick needle tag gun" is one of the important representatives of this change.

From manual to mechanical: how Qin Yu 8S tag gun changes traditional operation mode

In the past for a long time, the fixed label work mainly depends on manual operation. This method is not only time-consuming and laborious, but also easily leads to uneven product quality. However, since the introduction of Qin Yu 8S, an innovative tool, the situation has changed fundamentally-it can quickly and accurately realize various types of fabric marking tasks, greatly improving work efficiency and ensuring the consistency of the finished product.

The Power of Plastic Materials: Why Choose Robust Tool Materials

For environments that often need to be exposed to high-intensity use, it is important to choose the right raw materials. The Qin Yu brand has done in-depth research in this area, and finally determined to use high-quality engineering plastics to build the shell part of the product. This material has the following significant advantages:

- Strong impact resistance: It can remain intact even under harsh working conditions;

- Lightweight and easy to carry: Holding for a long time will not feel tired;

- Excellent corrosion resistance: It can resist the erosion of most chemical substances and extend the service life.

Strengthening the Secret of Thick Needles: Unique Design Value Analysis for Multi-class Material Processing

In addition, in order to meet the needs of different types of fabrics, the R & D team specially configured a set of thickened steel needle components after special treatment. They have the following features:

- Strong penetrating ability: Even in the face of very thick and hard materials, they are not afraid;

- Accurate and reliable positioning: Each shot can reach the expected position to ensure a tight and stable connection;

- Long life: Long-term frequent use can still maintain a good condition to reduce the frequency of replacement and reduce costs.

Production Efficiency Improvement Example Sharing: Real Case Showing Practical Application Effect of Qin Yu 8S

Let's take a look at some specific examples! After a well-known sportswear manufacturer introduced this equipment, it was found that the average daily output increased by about 30%, while the defective product rate decreased by more than one percentage point. In addition, many small studios have reported that using this system has enabled them to undertake larger-scale orders and expand their market scope and achieved good economic returns.

The secret behind easy maintenance: tips and maintenance suggestions for extending service life

Finally, it is worth mentioning that although the machine already has a considerable degree of self-protection mechanism, correct and reasonable post-care is still essential. For example, regular cleaning of internal residual fiber debris to prevent clogging and timely application of appropriate amount of lubricating oil to lubricate moving parts to reduce wear speed are good habits worth promoting. As long as you follow the instructions, you can keep this sharp weapon in your hand in its best working condition for many years.